Products >

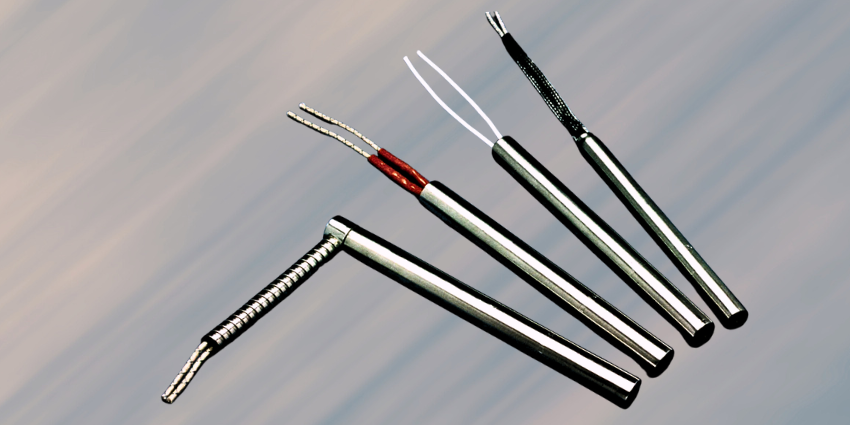

Cartridge Heaters

Cartridge-Heaters

Precision Heating for Industrial Applications

Calgen Cartridge Heaters, available in both High-Density (HWD) and Low-Density (LWD) types, are engineered to deliver efficient and precise heating solutions for a wide range of industrial applications including dies, platens, molds, core heating, and more. Designed with advanced materials and construction, these heaters offer excellent thermal transfer, long service life, and reliable performance even under demanding conditions.

High-Density Cartridge Heaters (HWD)

Application : High-density cartridge heaters are ideal for applications requiring intense and localized heating in compact spaces. Common uses include:

Packaging, sealing, and marking machines

Mold and die heating

Medical and laboratory equipment

Immersion heating

R&D and specialized industrial applications

Key Features and Benefits

High watt density for maximum heat output

Operates efficiently in vibration-prone environments

Withstands temperatures up to 1000°C

Compact design enables heating in limited space

Sheaths available in Type 316 stainless steel

Welded end disc for durability (3/8″ and above)

Thermocouple integration for accurate temperature control

Construction Details:

The resistance wire is tightly wound around a high-temperature refractory core, enclosed in a stainless steel sheath, and compacted with magnesium oxide to maximize heat transfer and durability. These heaters are ground to -0.001″ for optimal fit in reamed holes.

Low-Density Cartridge Heaters (LWD)

Application : Designed for gentle and even heating, low-density cartridge heaters are best suited for:

Dies and platens

Core heating

Applications requiring moderate heat without risking material damage

Key Features and Benefits

Lower surface temperature

Uniform heat distribution

Suitable for applications where overheating must be avoided

Made with insulated windings to reduce heat concentration

Construction Details:

Resistance wire is wound around ceramic insulators and inserted into metal tubes filled with magnesium oxide but not compacted like HWD heaters. This results in softer heat suitable for sensitive applications.

Technical Specifications:

Surface Ratings: Up to 100 W/in² (HWD)

Sheath Temperature: Max 600°C (Stainless steel), 300°C (Brass)

Voltage Options: 12V, 42V, 110–125V, 220–250V

Diameters Available: 1/4″, 5/16″, 3/8″, 1/2″, 5/8″ and metric sizes

Lengths: 1/4″ & 5/16″: 1″ to 4″

3/8″, 1/2″, 5/8″: 2.25″ to 12″+ depending on wattage

Installation & Operation Guidelines

Mounting: Insert into precision-drilled holes for tight thermal contact

Insulation: Proper external insulation enhances heating efficiency

Temperature Control: Use PID controllers and thermocouples for accurate regulation

Material Compatibility: Stainless steel sheath offers resistance to corrosion and high heat

Orientation: Suitable for both horizontal and vertical mounting

Safety & Maintenance Tips

- Use thermal cutoffs or alarms to avoid overheating

- Ensure proper electrical connections and insulation

- Regularly inspect and clean the heater and its surroundings

- Monitor for wear, corrosion, or damage to maintain performance

Why Choose Calgen by India Heaters?

With decades of expertise in industrial heating technology, Calgen by India Heaters ensures unmatched reliability, high thermal performance, and compatibility with a wide range of machinery and processes. Whether you need focused high heat or gentle temperature control, our cartridge heaters are designed to meet your exact operational requirements.

HWD Cartridge Heaters with standard dia and length

| L | 6mmD | 8mmD | 10mmD | 16mmD | 1/4"D | 3/8"D | 1/2"D | 5/8"D | 3/4"D |

|---|---|---|---|---|---|---|---|---|---|

| 40 | - | 100 | 100 | 200 | - | 100 | 150 | 200 | - |

| 50 | 100 | 100 | 200 | 200 | 100 | 200 | 200 | 200 | - |

| 60 | 100 | 150 | 200 | 200 | - | 200 | - | 200 | - |

| 70 | - | 200 | - | - | - | - | - | - | |

| 75 | 150 | 200 | 250 | 300 | 200 | 250 | 300 | 300 | - |

| 80 | - | 200 | 250 | - | - | 250 | - | - | - |

| 90 | - | 250 | 300 | - | - | 300 | 350 | - | - |

| 100 | 300 | 250 | 400 | 600 | 300 | 400 | 400 | 600 | - |

| 110 | - | 250 | 300 | - | - | 300 | 400 | - | - |

| 120 | - | 250 | 500 | - | - | 500 | 450 | - | - |

| 125 | 400 | 350 | 500 | 750 | - | 500 | 500 | 750 | - |

| 130 | - | 300 | - | - | - | - | - | - | - |

| 140 | - | 300 | 500 | - | - | 500 | 500 | - | - |

| 150 | - | 350 | 600 | 1000 | - | 600 | 600 | 1000 | 1000 |

| 160 | - | - | 550 | - | - | 550 | 600 | - | - |

| 175 | - | - | 600 | - | - | 600 | 700 | - | - |

| 200 | - | - | 700 | 1200 | - | 700 | 800 | 1200 | 1500 |

| 225 | - | - | 800 | - | - | 800 | 900 | - | |

| 250 | - | - | 800 | 1500 | - | 800 | 1000 | 1500 | 2000 |

| 275 | - | - | - | - | - | - | - | - | - |

| 300 | - | - | - | - | - | - | 1500 | - | - |

Cartridge Heaters - Brass Sheathed / SS Sheathed (Low Watt Density) – Heaters are also Available In 9.7,10,12,15mm.

| LENGTH | 3/8” D | 1/2” D | 5/8” D | 3/4” D | 7/8” D | 1” D | 1 1/4” D |

|---|---|---|---|---|---|---|---|

| 2.5” | 85w | 100W | 150W | 150W | 175W | 200W | - |

| 3” | 100W | 125W | 175W | 175W | 200W | 225W | - |

| 3.5” | 120W | 150W | 200W | 225W | 250W | 275W | - |

| 4” | 140W | 175W | 225W | 250W | 275W | 300W | 500W |

| 4.5” | 150W | 200W | 250W | 275W | 325W | 350W | 500W |

| 5” | 175W | 225W | 275W | 300W | 350W | 400W | 500W |

| 5.5” | 190W | 250W | 300W | 350W | 400W | 450W | 500W |

| 6” | 200W | 275W | 325W | 375 | 425W | 475W | 500W |

| 7” | 250W | 300W | 375W | 450 | 500W | 500W | 750W |

| 8” | 275W | 350W | 450W | 500 | 550W | 600W | 750W |

| 9” | 300W | 400W | 475W | 550 | 625W | 700W | 1000W |

| 10” | 350W | 450W | 550W | 625 | 700W | 800W | 1000W |

| 11” | 375W | 500W | 600W | 700 | 800W | 875W | 1000W |

| 12” | 400W | 550W | 650W | 750 | 850W | 950W | 1500W |

| 15” | - | - | 800W | 950 | 1050W | 1200W | - |

| 18” | - | - | 1000W | 1100 | 1250W | 1400W | - |

| 24” | - | - | 1300W | 1500 | 1700W | 1900W | - |

India Heaters

No. 34, 3rd Block, 3rd Floor, 14th Cross, IV Phase, MS Industrial Complex, Peenya IInd Stage, Above Sub Register Office Bengaluru – 560058, Karnataka, India