Products >

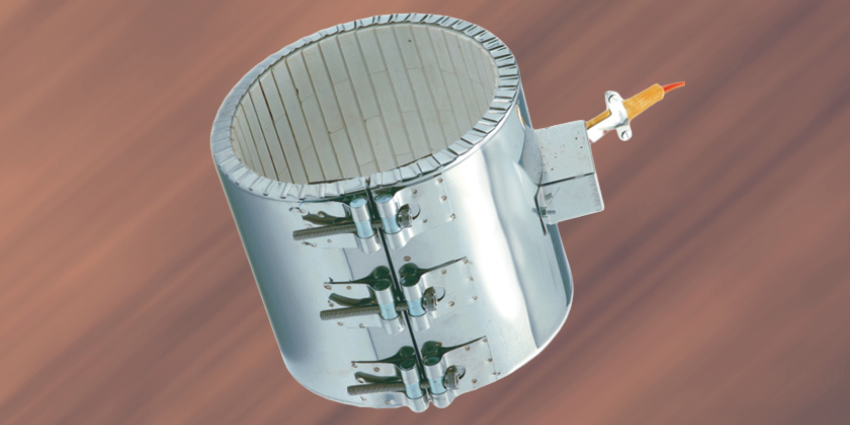

Ceramic Band Heaters

Ceramic Band Heaters

High-Performance Heating for Cylindrical Surfaces

Looking for reliable, efficient heating for barrels, pipes, and cylindrical machinery? Our Ceramic Band Heaters are built to deliver high temperatures, uniform heat distribution, and long-term durability. Perfect for industries requiring precise and consistent thermal performance.

What Are Ceramic Band Heaters?

Ceramic band heaters are industrial heating elements specifically designed to heat cylindrical surfaces like extruder barrels and injection moulding machines. These heaters combine ceramic insulation with nickel-chrome resistance wires, all encased in a durable metal sheath for excellent thermal performance and mechanical strength.

Key Construction Features

Ceramic Core: Interlocking ceramic tiles offer superior thermal insulation and withstand high temperatures.

Nickel-Chrome Wire: Helically wound resistance wire generates consistent heat and is embedded within the ceramic body.

Metal Sheath: Stainless steel or aluminized steel housing protects the inner components and distributes heat evenly.

Additional Insulation: Optional ceramic fiber layer reduces heat loss, improves efficiency, and enhances safety.

Applications Across Industries

Ceramic band heaters are widely used in:

Plastic Processing – Barrel heating in injection moulding and extrusion machines

Semiconductor Industry – Component heating in clean environments

Die Casting – Maintaining mold temperatures

Food Processing – Oven and equipment heating

Packaging Industry – Heat sealing in automated systems

General Industrial Use – Heating tanks, drums, and pipes

Design Options Available

Choose from a variety of custom features:

Hinged or split band types for easy installation

Flexible and elliptical shapes

Two or three heat zones

Built-in thermocouple holes or slots

Clamping options: Slide clips or separate bands

Technical Specifications

Heating Methods: Uses both conduction and radiant heat transfer

Operating Temperature: Up to 760°C (1400°F)

Diameter Range: 75mm to 20″ in one-piece designs

Widths Available: From ¾” to 12″

Surface Wattage: Up to 25 W/in²

Terminations: 12″ insulated leads (standard), or terminal housings

Gap Allowance: Minimum cold gap of ¼” for optimal installation

Note: For the best heat transfer, the heater diameter should be larger than the width.

Why Choose Our Ceramic Band Heaters?

High Temperature Handling – Ideal for demanding heating applications

Energy Efficient – Minimal heat loss with ceramic insulation

Long Lifespan – Built from robust and heat-resistant materials

Custom Sizes – Designed to match your exact machine requirements

Fast Installation – Easy to install, remove, and maintain

Even Heating – Consistent performance over the entire surface area

Available Types

Standard Ceramic Band Heaters – Reliable and cost-effective

Insulated Ceramic Band Heaters – Added insulation for better efficiency

Perforated Ceramic Band Heaters – Enhanced air circulation for cooling

How to Choose the Right Heater?

When selecting a ceramic band heater, consider the following:

Desired operating temperature

- Required wattage and voltage

- Size and shape of the surface to be heated

- Insulation needs and energy efficiency

- Suitable termination style for your wiring

Need a custom solution?

Contact us today for expert advice or request a quote tailored to your specifications. Let us help you power your process with precision heating.

India Heaters

No. 34, 3rd Block, 3rd Floor, 14th Cross, IV Phase, MS Industrial Complex, Peenya IInd Stage, Above Sub Register Office Bengaluru – 560058, Karnataka, India