Products >

Heaters for Electro Plating Industry

Electroplating Heaters

Precision-Engineered Heaters for Electroplating Applications

India Heaters, under the registered brand name Calgen, offers top-tier industrial heaters specifically designed for electroplating applications. Our heaters ensure precise temperature control, corrosion resistance, and efficient performance, vital for achieving high-quality electroplated finishes.

Calgen by India Heaters provides a wide variety of heaters tailored to meet the specific demands of electroplating processes. Our product range includes:

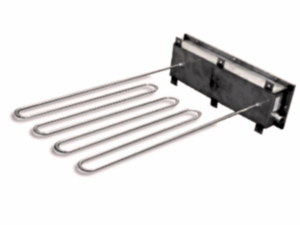

Immersion Heaters – Designed for heating plating baths and chemical solutions, ensuring even heat distribution.

PTFE-Coated Heaters – Ideal for use in highly corrosive environments, providing long-lasting performance.

Quartz Heaters – Perfect for aggressive plating solutions that require chemical resistance.

Over-the-Side Heaters – Easily installed without draining the tank, suitable for both maintenance and continuous operation.

Flanged Heaters – Suitable for large tanks, offering efficient heating and straightforward installation.

Key Features and Benefits

Corrosion Resistance – Our heaters are built with PTFE, titanium, and quartz sheaths to withstand harsh electroplating environments.

Customizable Solutions – We offer heaters tailored to specific tank sizes, solution types, and operational requirements.

Energy Efficient – Calgen heaters are designed to reduce energy consumption while delivering consistent and reliable performance.

Durable and Long-Lasting – Manufactured using high-quality materials to ensure longevity and minimize downtime.

Industrial Applications

Calgen heaters by India Heaters are essential for various electroplating applications, including:

- Metal Plating – Ensuring uniform heating for high-quality surface finishes.

- Electroless Plating – Maintaining bath temperatures for consistent and reliable plating results.

- Anodizing – Facilitating temperature control for effective anodizing processes.

- Surface Treatment – Supporting various chemical and electrochemical surface finishing processes.

Copy of Cartridge Heaters - Brass Sheathed / SS Sheathed (Low Watt Density) – Heaters are also Available In 9.7,10,12,15mm.

| Type | Watts | Volts | Vertical Length | Cold Zone |

|---|---|---|---|---|

| CAIH/10/460 | 1000 | 230 | 460 | 150 |

| CAIH/20/610 | 2000 | 230 | 610 | 150 |

| CAIH/30/685 | 3000 | 230 | 685 | 300 |

| CAIH/40/685 | 4000 | 230 | 685 | 300 |

| CAIH/10/540 | 1000 | 230 | 540 | 150 |

| CAIH/20/730 | 2000 | 230 | 730 | 300 |

| CAIH/30/870 | 3000 | 230 | 870 | 300 |

| CAIH/40/1000 | 4000 | 230 | 1000 | 300 |

| CAIH/50/1300 | 5000 ` | 230 | 1300 | 300 |

| CAIH/60/1540 | 6000 | 230 | 1540 | 300 |

These heating elements can be supplied in SS304/316/316L/Incoloy /Titanium / Lead covered / Teflon coating can be added.

Specify the chemical / Acid to heat, to enable us to suggest heater sheath if something is not listed in below sheath selection chart.

Thermowell Heaters for vertical use (With renewable element interiors)

These heaters can be supplied in Silica, lead bonded, glass, stainless steel, mild steel, Titanium tube with with clamp plate of 75mm X 100mm or 100mm X 125 mm For tank heating – suitable for water, oils, acids,tar, waxes and paraffin, alkaline solutions, anodising and plating baths.

Titanium heaters are used in Nitric and Chromic acid solutions.

This vertical mounting heaters comes with element interiors easily replaceable. None of the heaters should be supported by the cap or cable alone.

Thermowell Heaters for vertical use

| Type | Watts | Volts | Sheathing | HZ | CZ | Length | Clamp | Dia |

|---|---|---|---|---|---|---|---|---|

| CTW/T/500/300 | 500 | 230 | TITANIUM | 225 | 150 | 300MM | 50x50 | 25/38/50 |

| CTW/T/10/450 | 1000 | 230 | TITANIUM | 350 | 100 | 450MM | 75X100 | 25/38/50 |

| CTW/T/20/600 | 2000 | 230 | TITANIUM | 450 | 150 | 600MM | 75X100 | 25/38/50 |

| CTW/T/30/750 | 3000 | 230 | TITANIUM | 550 | 200 | 750MM | 75X100 | 25/38/50 |

| CTW/T/40/900 | 4000 | 230 | TITANIUM | 700 | 200 | 900MM | 75X100 | 25/38/50 |

| CTW/SS/10/300 | 1000 | 230 | SS304 | 100 | 200 | 300MM | 100 X125 | 25/38/50 |

| CTW/SS/15/450 | 1500 | 230 | SS304 | 300 | 150 | 450MM | 100 X 125 | 25/38/50 |

| CTW/SS/20/600 | 2000 | 230 | SS304 | 450 | 150 | 600MM | 100 X 125 | 25/38/50 |

| CTW/SS/30/750 | 3000 | 230 | SS304 | 550 | 200 | 750MM | 100 X 125 | 25/38/50 |

| CTW/SS/40/900 | 4000 | 230 | SS304 | 700 | 200 | 900MM | 100 X 125 | 25/38/50 |

| CTW/MS/10/300 | 1000 | 230 | M.S | 100 | 200 | 300MM | 100 X125 | 25/38/50 |

| CTW/MS/15/450 | 1500 | 230 | M.S | 300 | 150 | 450MM | 100 X 125 | 25/38/50 |

| CTW/MS/20/600 | 2000 | 230 | M.S | 450 | 150 | 600MM | 100 X 125 | 25/38/50 |

| CTW/MS/30/750 | 3000 | 230 | M.S | 550 | 200 | 750MM | 100 X 125 | 25/38/50 |

| CTW/MS/40/900 | 4000 | 230 | M.S | 700 | 200 | 900MM | 100 X 125 | 25/38/50 |

Thermowell Heaters For Horizontal Mounting (With renewable element interiors)

The elements are easily replaceable, and are supplied with 1”, 1.25”, 2” , 2.5” bsp head. Heavy duty heater is supplied with substandard (as per your requirement/design) or standard ansi flange

Thermowell Heaters For Horizontal Mounting

| Type | Watts | Volts | Sheathing | Imm. Depth | Flang | Hot Zone | Dia |

|---|---|---|---|---|---|---|---|

| CTW/H/SS/.5/300 | 500 | 230 | S.S | 300MM | 1.5”/2” bspt | 75MM | 25/38mm |

| CTW/H/SS/10/300 | 1000 | 230 | S.S | 300MM | 1.5”/2” bspt | 75MM | 38mm |

| CTW/H/SS/15/300 | 1500 | 230 | S.S | 300MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/SS/20/450 | 2000 | 230 | S.S | 450MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/SS/20/600 | 2000 | 230 | S.S | 600MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/SS/30/600 | 3000 | 230/415 Y | S.S | 600MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/SS/30/750 | 3000 | 230/415 Y | S.S | 750MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/SS/40/750 | 4000 | 230/415 Y | S.S | 750MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/SS/40/900 | 4000 | 230/415 Y | S.S | 900MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/SS/50/900 | 5000 | 230/415 Y | S.S | 900MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/MS/.5/300 | 500 | 230 | M.S | 300MM | 1.5”/2” bspt | 75MM | 25/38mm |

| CTW/H/MS/10/300 | 1000 | 230 | M.S | 300MM | 1.5”/2” bspt | 75MM | 38/50mm |

| CTW/H/MS/15/300 | 1500 | 230 | M.S | 300MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/MS/20/450 | 2000 | 230 | M.S | 450MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/MS/20/600 | 2000 | 230 | M.S | 600MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/MS/30/600 | 3000 | 230/415 Y | M.S | 600MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/MS/30/750 | 3000 | 230/415 Y | M.S | 750MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/MS/40/750 | 4000 | 230/415 Y | M.S | 750MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/MS/40/900 | 4000 | 230/415 Y | M.S | 900MM | 2” bspt | 75MM | 38/50mm |

| CTW/H/MS/50/900 | 5000 | 230/415 Y | M.S | 900MM | 2” bspt | 150MM | 38/50mm |

Why Choose Calgen by India Heaters?

India Heaters, through the Calgen brand, has established itself as a leader in providing high-performance heating solutions for industrial applications. Our dedication to quality, innovation, and customer satisfaction ensures that our heaters deliver unmatched efficiency and durability.

Get in touch with India Heaters today to learn how Calgen electroplating heaters can enhance your plating processes, improve product quality, and ensure operational excellence.

India Heaters

No. 34, 3rd Block, 3rd Floor, 14th Cross, IV Phase, MS Industrial Complex, Peenya IInd Stage, Above Sub Register Office Bengaluru – 560058, Karnataka, India