Products >

Tubular Heaters

Tubular Heaters

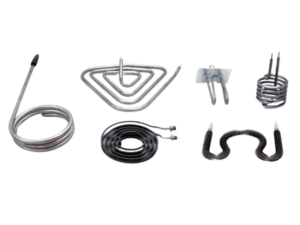

Versatile and Durable Tubular Heaters for Industrial Applications

India Heaters, Heaters India tubular heaters are the most versatile and widely used source of heat throughout the industry, for commercial, industrial and scientific heating applications. The Basic construction of a tubular heater – it is a helical coil of nickel chromium alloy wire, precisely centered in a metal tube. Surrounding the coil is the best combination of electrical insulator and heat conductor Magnesium Oxide. After the tube is filled with MgO, it is compacted by rolling or swaging. This elongates the tube, thickens the wire and compresses the MgO into rock hard mass. The coil is thus permanently stabilized in the centre of the tube where it will not shift during the bending process; the circular cross section with its even distribution of the forces of expansion offers the best combination of life, thermal conductivity and die-electric strength.

Salient Features includes:

Straight Tubular Heaters – Suitable for insertion into ducts, pipes, and platens for direct or radiant heating.

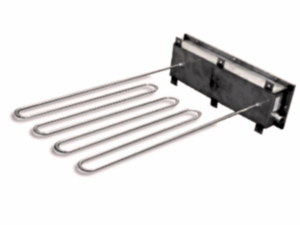

U-Shaped Tubular Heaters – Designed for immersion in liquids, air heating, and surface heating applications.

Finned Tubular Heaters – Ideal for enhanced heat transfer in air heating systems, reducing energy consumption.

Flanged Tubular Heaters – Perfect for heating large tanks and vessels with efficient heat distribution.

Flexible Tubular Heaters – Adaptable to custom shapes and surfaces, providing heating in hard-to-reach areas.

Key Features and Benefits

HEAT OUTPUT: The highest quality materials and construction techniques enable HI tubular heaters to offer the maximum heat output (max., watts per sq., inch of sheath surface) at any given temperature. The same factors provide the longest possible operating life under less severe conditions.

Versatility: Heaters India tubular heaters can be designed in a wide range of electric ratings, diameters, lengths and sheath materials, with various termination styles. Due to the construction characteristics, the heating element is electrically isolated from the sheath. This allows for forming them into virtually any shape – wrap around machine parts, brazed or welded to any metal surface, cast into metals immersed in liquids or used as convection or radiant heaters.

Reliability: Heaters India Tubular heaters are unequaled in their resistance to shock, vibration, corrosion, high-temperature and moisture condensations. They are unexcelled by any other form of electric heating element for reliability and ruggedness.

Economy: When high temperature, physical and electrical strength are required, Heaters India tubular heaters provide the most economical solution to hundreds of heating applications.

Applications:

Combination radiant and convection heaters for ovens, air spaces between containers and outside walls and thermoforming machines.

Contact heaters placed in grooves, milled in metal plates, wrapped around or laid alongside pipes, held against metal containers.

Cast-in heaters are formed tubular heaters placed in aluminum, brass, or silicon bronze castings. Typical uses are for heat sealing platens, barrel heating of extruders, and plastic injection molding machines. Heating of irregular or non-symmetrical surfaces and cast tanks with built in heaters.

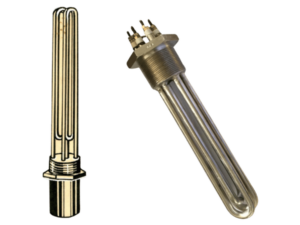

Tubular heaters are often used to heat substances directly. Typical examples are steam boilers, and laboratory water baths.

Tubular heaters can be supplied four ways, welded or brazed to bulk head fittings, steel plates, pipe flanges, and N.P.T pipe plugs.

Basic sheath recommendations

COPPER: Ideally suited for water heating and water solutions non-corrosive to copper.

STEEL: For immersion in circulating and non-circulating oils, alkaline cleaning solutions, molten salt drawing and tempering baths, molten soft metals, waxes and puffins, heavy compounds such as tars and asphalts. Steel sheath heaters are also suitable for clamping to metal surfaces, casting into aluminum or bronze.

STAINLESS STEEL: Primarily used for corrosive substances and food processing equipments.

INCOLOY: Typical applications are radiant heating, immersion in plating and pickling solutions, oils, cleaning and degreasing solutions, molten salts and heavy compounds where materials are corrosive to steel, immersion in vapor degreasing solutions containing free acids and immersion in mineral oils. Incoloy sheath heaters can also be applied to air heating, casting into iron and clamping to metal surfaces.

The proper selection of sheath materials and watt density rating is essential for good heater life and trouble free service.

Industrial Applications

Calgen tubular heaters by India Heaters are essential for numerous industrial processes, including:

- Plastic Moulding – Ensuring precise heating for moulds and extrusion systems.

- Chemical Processing – Heating tanks, pipelines, and chemical baths with precision.

- Textile Industry – Supporting drying, curing, and heat-setting processes.

- Food Processing – Facilitating baking, drying, and other food production operations.

- HVAC Systems – Providing efficient air and liquid heating in ventilation and heating systems.

Water Immersion Heaters (Domestic)

| Type | Watts | Volts | Imm. Depth | Flange |

|---|---|---|---|---|

| CWH/C/10/22 D | 1000 | 230 | 220 | 1.25”BSPT |

| CWH/C/15/220D | 1500 | 230 | 220 | 1.25”BSPT |

| CWH/C/20/325 D | 2000 | 230 | 325 | 1.25”BSPT |

| CWH/C/30/425 D | 3000 | 230 | 425 | 1.25”BSPT |

Water Immersion Heaters (Industrial)

Heating elements can be supplied either in SS or copper and also with or without thermostat.| Type | Watts | Volts | Imm. Depth | Flange |

|---|---|---|---|---|

| CWIH/I/20/220 D | 1000 | 230 | 220 | 1.25”BSPT |

| CWIH/I/20/220 D | 2000 | 230 | 220 | 1.25”BSPT |

| CWIH/I/30/280 D | 3000 | 230 | 280 | 1.25”BSPT |

| CWIH/I/30/220 D | 3000 | 230/415 | 220 | 1.25”BSPT |

| CWIH/I/30/220 D | 3000 | 230/415 | 220 | 1.50”BSPT |

| CWIH/I/40/260 D/T | 4000 | 230/415 | 260 | 2” BSPT |

| CWIH/I/50/320 D/T | 5000 | 230/415 | 320 | 2” BSPT |

| CWIH/I/60/380 D/T | 6000 | 230/415 | 380 | 2” BSPT |

| CWIH/I/90/550 D/T | 9000 | 230/415 | 550 | 2” BSPT |

Kettle Elements

| Type | Watts | Volts | Imm. Depth | Flange |

|---|---|---|---|---|

| CKE/10/115 | 1000 | 230 | 115 | 1.25”BSPT |

| CKE/15/115 | 1500 | 230 | 115 | 1.25”BSPT |

| CKE/20/115 | 2000 | 230 | 115 | 1.25”BSPT |

| CKE/25/135 | 2500 | 230 | 135 | 1.25”BSPT |

| CKE/30/160 | 3000 | 230 | 160 | 1.25”BSPT |

U Shaped Water Heaters

Temperature control: Normally 30-90deg can be controlled by in-built thermostat, beyond 90deg temp/. (Controlled by contactor).| Type | Watts | Volts | Vertical Length | Nipples |

|---|---|---|---|---|

| CUWH/.25/220 | 250 | 230 | 220MM | M12/M15 |

| CUWH/.50/220 | 500 | 230 | 220MM | M12/M15 |

| CUWH/.75/220 | 750 | 230 | 220MM | M12/M15 |

| CUWH/10/220 | 1000 | 230 | 220MM | M12/M15 |

| CUWH/15/220 | 1500 | 230 | 220MM | M12/M15 |

| CUWH/20/220 | 2000 | 230 | 325MM | M12/M15 |

| CUWH/25/220 | 2500 | 230 | 380MM | M12/M15 |

| CUWH/30/220 | 3000 | 230 | 430MM | M12/M15 |

Oil Immersion Heaters

Temperature control: Normally 30-90deg can be controlled by in-built thermostat, beyond 90deg temp/. (Controlled by contactor).Oil immersion heaters can be supplied in different flanges like 1.25”/1.5”/2” & in circular flanges with/without thermostat.

| Type | Watts | Volts | Imm. Depth | Flange |

|---|---|---|---|---|

| COIH/10/435 | 1000 | 230 | 435 | 2.5”BSPT |

| COIH/15/435 | 1500 | 230 | 435 | 2.5”BSPT |

| COIH/20/435 | 2000 | 230 | 435 | 2.5”BSPT |

| COIH/30/435 | 3000 | 230/415 | 435 | 2.5”BSPT |

| COIH/40/575 | 4000 | 230/415 | 435 | 2.5”BSPT |

| COIH/50/575 | 5000 | 230/415 | 435 | 2.5”BSPT |

| COIH/60/575 | 6000 | 230/415 | 435 | 2.5”BSPT |

| COIH/90/575 | 9000 | 230/415 | 435 | 2.5”BSPT |

Why Choose Calgen by India Heaters?

India Heaters, through the Calgen brand, has built a reputation for delivering advanced heating solutions that drive industrial efficiency. Our commitment to quality, innovation, and customer satisfaction ensures that our tubular heaters meet the highest performance standards, making them the preferred choice across industries.

Contact India Heaters today to explore how Calgen tubular heaters can enhance your industrial operations, improve productivity, and ensure long-term performance.

India Heaters

No. 34, 3rd Block, 3rd Floor, 14th Cross, IV Phase, MS Industrial Complex, Peenya IInd Stage, Above Sub Register Office Bengaluru – 560058, Karnataka, India